Plant data

General

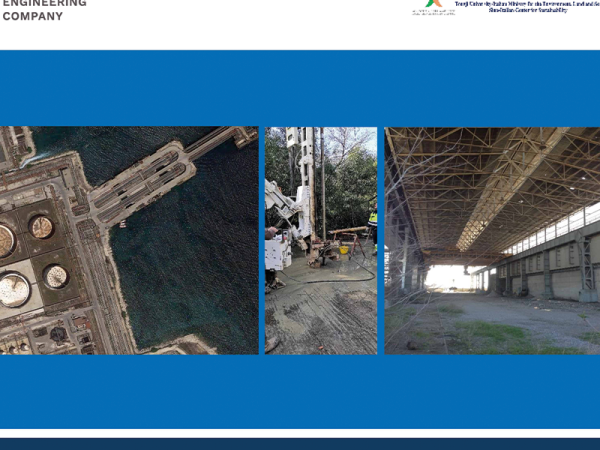

- Location: Calvisano (BS)

- Coord. UTM (Zone 32 T):

604.640 E – 5.024.618 N - Site area: ca. 12 ha

- Buildings surface: 8.000 m²

- Design period: 2015

- Task assigned and carried out: Preliminary design

- Cost: 47.631.955€

Technical Data

- Refuse derived fuel (RDF) production: mechanical separations, with metals and plastics recovery and RDF production. Capacity: 120.000 t/year

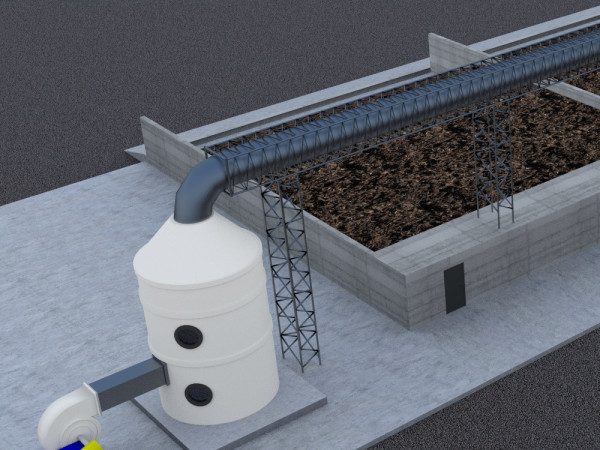

- Organic underscreen treatment: aerobic biostabilization in air-forced dynamic windrows. Capacity 60.000 t/year

- Organic waste treatment: anaerobic digestion and composting of the digested sludge. Capacity: 30.000 t/year. Biogas cogeneration: 1 MWe

- Biomass power plant: < 1MWe

Plant description

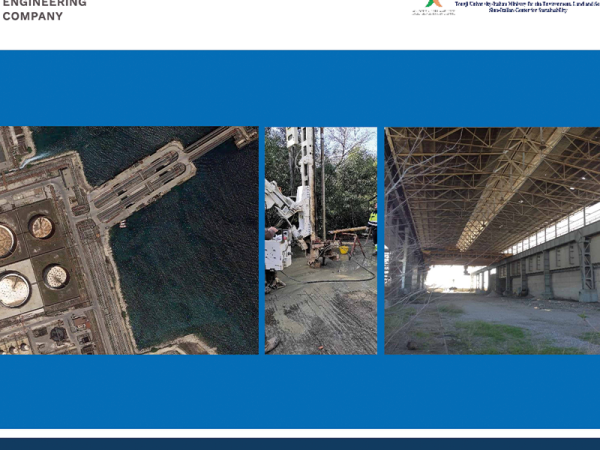

The proposed solution provides the conversion of a disused industrial site, a former steelworks plant that becomes a multifunctional platform for the community, paying attention to social issues, such as electricity production from renewables resources. One of the principal advantages of this site is the internal railway junction which offers a logistic alternative for road transport resulting in other benefits. Other advantages could be achieved if cross-border transportation would be implemented, obtaining useful and strategic industrial operations.

The project consists in the construction of two treatment lines for the separate collected dry waste to produce the RDF in the already existing building. Furthermore, a section for the aerobic biostabilization of organic underscreen waste coming from mechanical sorting of mixed urban waste will be built. In prospect of a future increase in separate collection of urban waste, a section for anaerobic digestion is planned too; the produced biogas will be exploited for cogeneration (combined production of heat and electricity) using endothermic engines. The project also consists of a biomass power plant for woodchips treatment. Therefore, the factory represents a stand-alone platform while social targets such as reducing the treatment costs of community waste and reducing the emission of gree house gases will be achieved.

Considering the goals of the project and the existing buildings on the site, the construction of internal laboratories for the factory management is planned, as well as the creation of a learning and development centre to provide training courses and applied research in cooperation with universities.