Plant data

Features

- Location: Lentini (SR)

- Coord. UTM (Zone 33S):

502,790 E – 4,135,670 N - Site area: 17.1 has

- Surface of the basins:

A: 41,800 m²

B: 35,500 m² - Total Volume: 1,914,000 m³

- Construction period: under construction

- Assignment: Final and executive design, AIA (Environmental Integrated Authorization) proceedings and construction management

- Cost: 40,195,425.48 €

Treatment

- Operations according to All. B and C at Part IV of D.Lgs. 152/06 s.m.i.: D1, D9, D15

- Maximum expeted potentiality:

350,000 ton/year - Expected operating life: 9 years

- Days of disposal per year: 320

- Maximum production of leachate expected: 50 m³/day

- Maximum theoretical biogas production expected: 5÷15 Nm³/ton waste x year

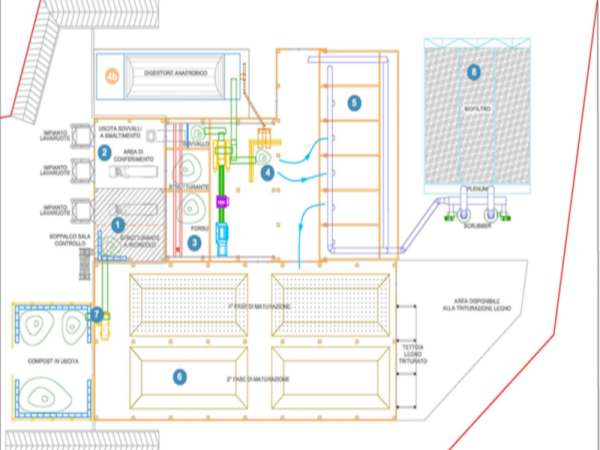

Accessory equipment

- Leachate treatment system which provides a stage of ultrafiltration with four reverse osmosis stages, with a potential of 50 m³/day

- Biogas treatment: cogeneration system for the production of electric energy

- n. 86 vertical wells for biogas collection

- n. 1 substation aspiration and regulation system

- biogas purification system

- n. 3 Jenbacher engines JGS312 and emergency flashlight

(S0009)

Plant description

The system falls into the category of landfills for the transfer of non-hazardous waste in accordance with D.Lgs. 36/03 and D.Lgs. 152/06, as amended.

The main type of transferred waste will be constituted by dry fraction coming from mechanical treatment (screening material), EWC code 191212 and stabilized wet fraction, EWC code 190503.

he plant consists of two distinct and separate basins, the first of which has a volume amounting to 1,100,000 m3 and the second has a volume amounting to 814,000 m3. Both basins are waterproofed in order to preserve the environmental matrices in accordance with the Legislative Decree no. 36/03. On the bottom of each basin a double network of uptake of the leachate produced by the delivered waste has been arranged, the first for the ordinary drainage and the second, the lower one, for the safety drainage. The networks of leachate belong to two separate wells for the collection and relaunching, in order to allow temporary storage of leachate within separate and dedicated units (steel tanks above ground), the leachate is finally started, within the same landfill site, to the treatment facility, in which, through a physical-chemical process, it’s possible to obtain a clarified effluent (compatible with the limits established by D.Lgs. 152/06, for discharges into surface receptors water bodies) and a concentrate, which can be fed back into the body of the landfill.

The system is completed by a dedicated section for the aspiration, purification and enhancement of the biogas produced by the landfill during the vesting period and the post-mortem of the same.